AeroMetPro

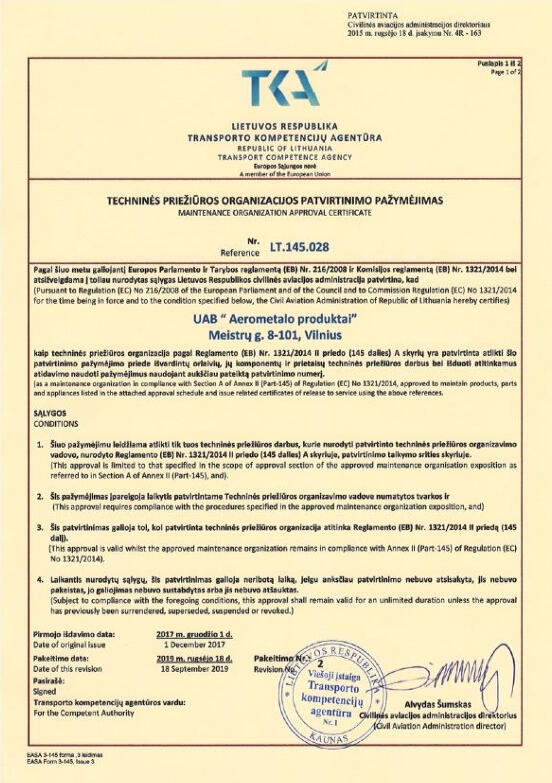

Aerometpro is a PART-145 certified MRO specializing in the overhaul of wheels, brakes, interior components, and structural parts for Airbus, Boeing, ATR, Embraer, and other aircraft.

We take pride in delivering high-quality, cost-effective overhaul (OH) services with fast turnaround times and full certification. Our in-house capabilities are designed to support the operational needs of both regional and commercial airlines.

About Us

Founded in 2016, Aerometpro is a PART-145 certified Maintenance, Repair, and Overhaul (MRO) provider based in Lithuania. We specialize in the maintenance, repair, overhaul, and manufacturing of high-quality aircraft components, serving airlines, MROs, and aircraft operators across Europe and beyond.

Our mission is to deliver fast turnaround times, precision workmanship, and uncompromising quality across every project we undertake.

Our Core Capabilities

• Wheels & Brakes Overhaul

• Battery and Inflatable Unit Services & Overhaul

• Aircraft Interiors Refurbishment – including seats, panels, and lavatories

• Component Maintenance – ATA Chapters C6 (Structures), C7 (Doors), C14 (Landing Gear)

• Aviation Tooling & Equipment Manufacturing – design and production of specialized tools and instruments for aircraft MRO applications

• Aviation Welding Services – certified structural and component welding solutions

With a skilled team and strategic industry partnerships, Aerometpro is committed to keeping aircraft flying safely, efficiently, and reliably.

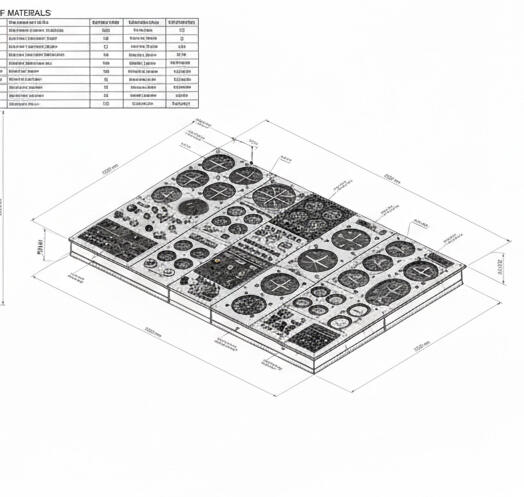

Aviation Tools

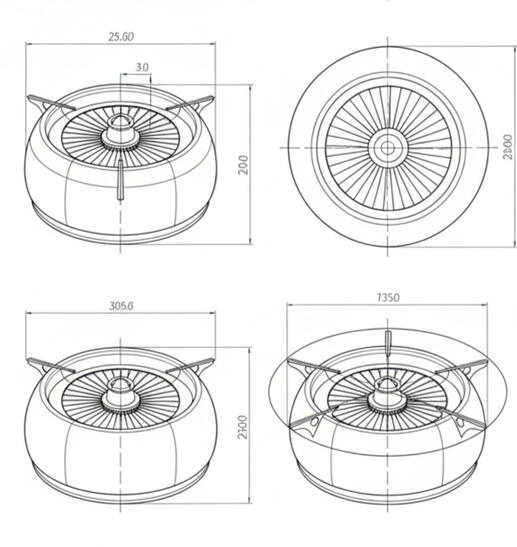

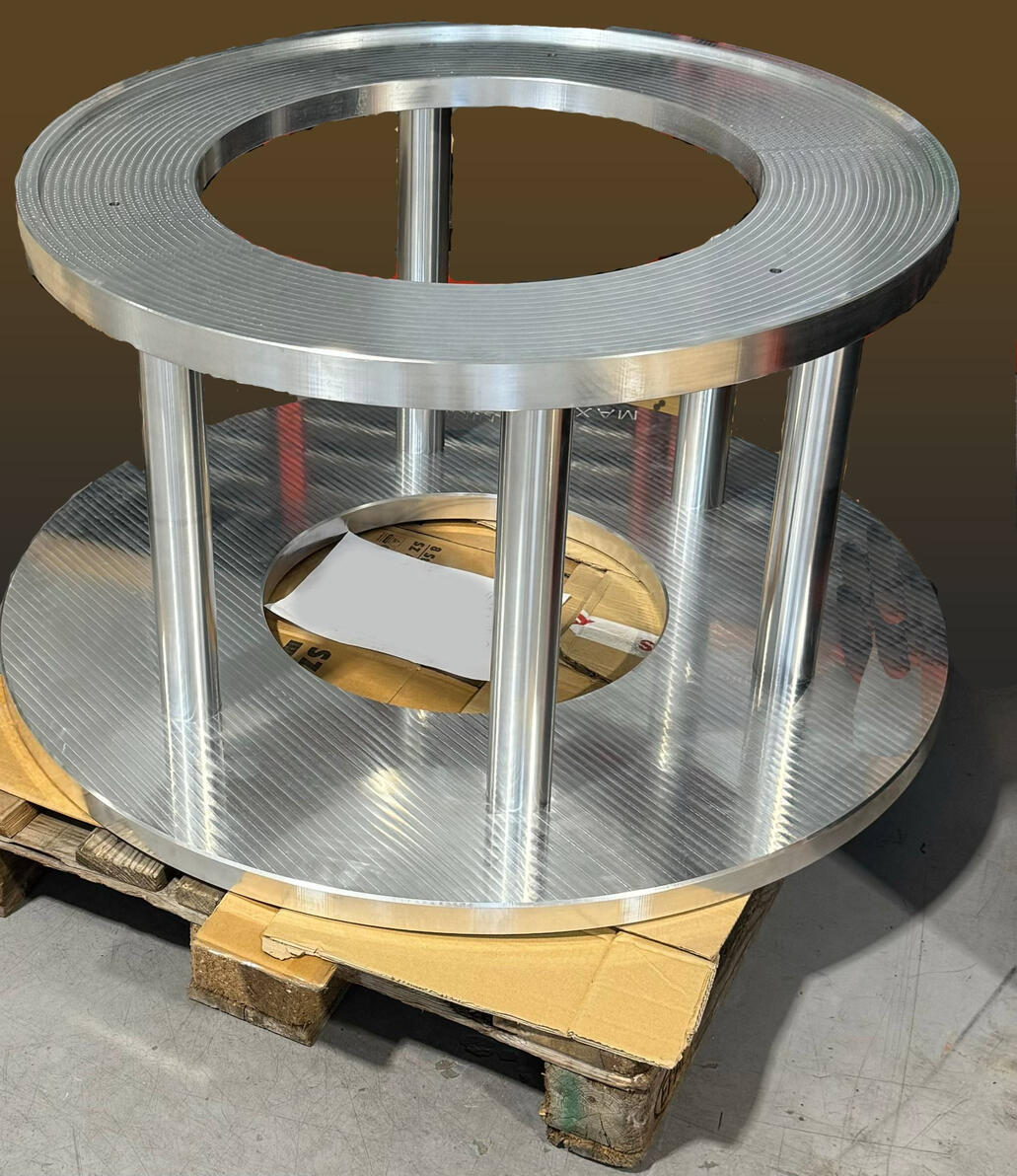

We manufacture equipment required for production and maintenance processes for aircraft parts manufacturers and servicing companies.

- Production of aviation equipment and tools based on provided drawings.

- Design of ground equipment, auxiliary tools for engine repair, and aircraft structural components.

- Load testing and comprehensive documentation preparation.

- CNC machining, heat treatment and application of galvanic coatings.

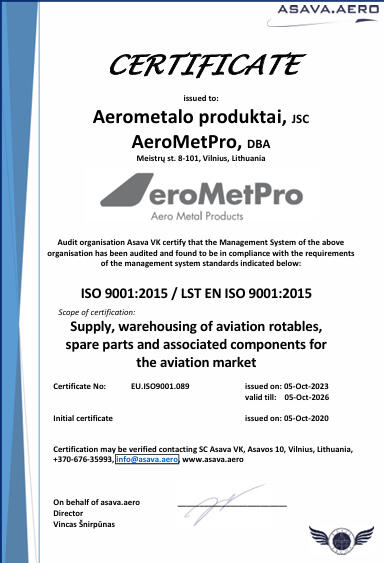

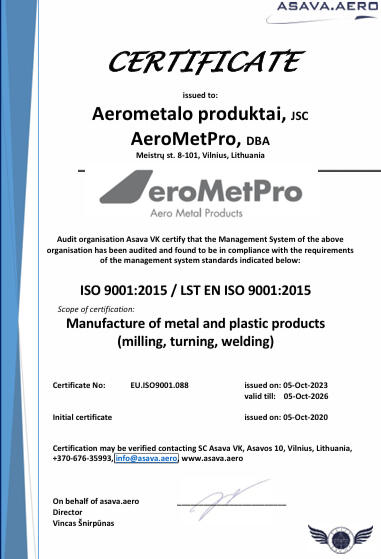

Our production adheres to the highest quality standards in compliance with EASA requirements and successfully undergoes the full certification process.

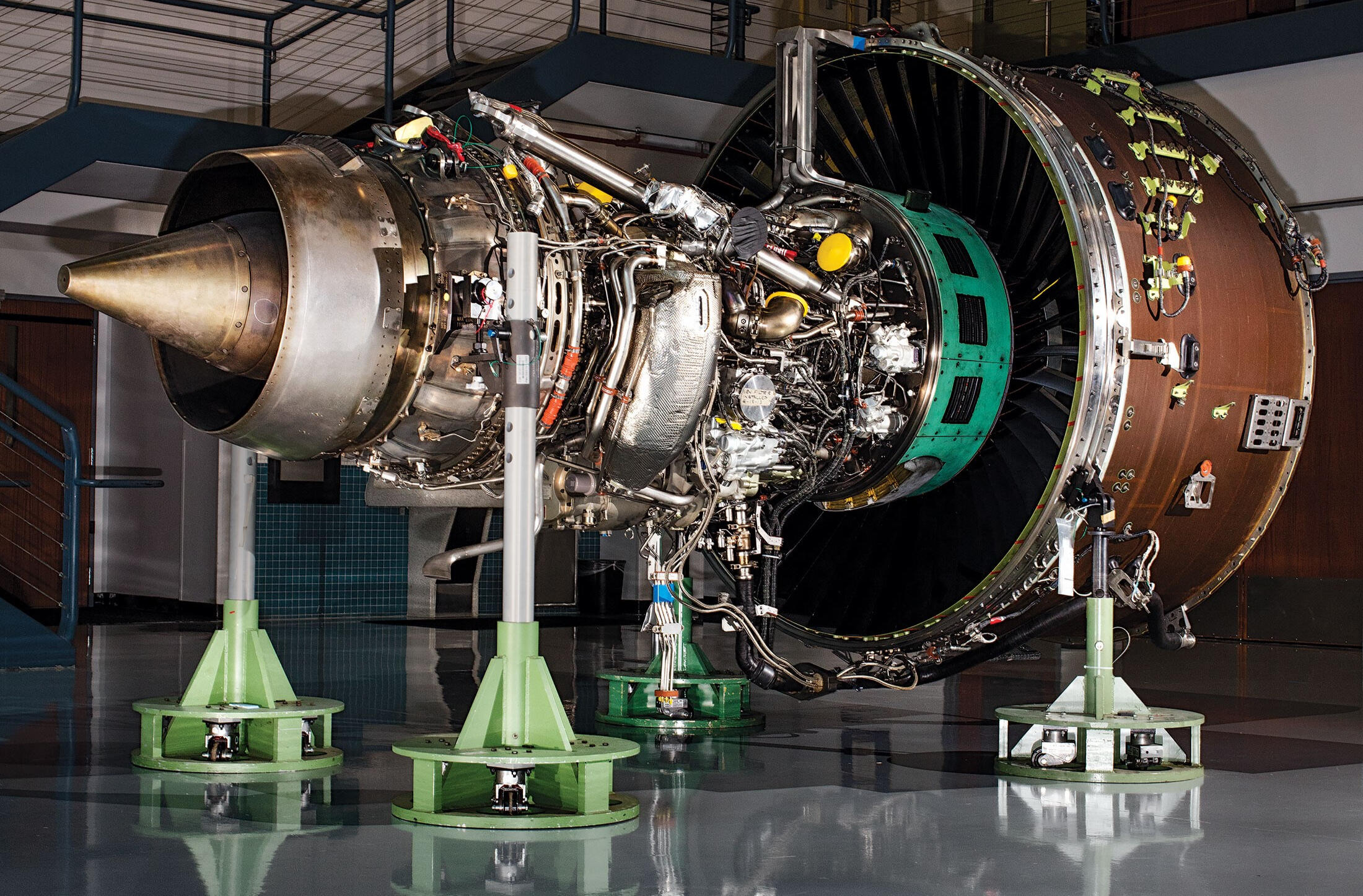

Our products include engine stands, engine assembly support tools, wheel and brake maintenance tools, aviation platforms, stands and others.

Our product lineup includes pedestal support engine assemblies, adapter pedestal adjust tables, stand handling fan cases and FDC horizontals, stand-built bearing housing heat shields and others.

AeroMetPro excels in industrial metallurgy. We offer precision manufacturing and the flexibility to handle custom designs, client-provided blueprints, and single-unit and mass production. Our advanced machinery and expertise ensure timely delivery and superior quality across all production phases. We can work with materials like steel, aluminium, titanium and plastics, producing a wide range of mechanical parts, from small components to large structures.

Welding

AeroMetPro is the only EASA Part-145 Certified company in Lithuania for Fusion Welding for Aerospace Applications, including – but not limited, to various Aluminium, Titanium and Stainless steel alloys welding using Gas tungsten arc welding (GTAW).

Works can be performed on board the aircraft or removed components by issuing CofC or EASA F1 with status repaired.

With suppliers of repair materials worldwide and qualified technicians on-site, we can perform work in the shortest terms and at competitive prices.

Wheels and Brakes

• EASA Part-145 certified in-house overhaul, inspection, and testing of aircraft wheels and brakes.

• Capability for steel and carbon brake assemblies, including overhaul, inspection, re-lining and testing.

• Expertise across most popular Airbus, Boeing, ATR and other regional aircraft platforms.

• Minimize downtime with fast TATs and cost-effective parts. We maintain a wide range of components in stock and offer consignment programs upon.

• Overhaul service agreements tailored for airlines.

Aircraft cabin interiors

We are dedicated to delivering top-notch aircraft interior services, ensuring the highest level of quality for your flying experience.• Part 145 Maintenance and repair

• PAX seat and component release to service

• Re-certification with EASA Form1

• Interior components supply

• Part-out and release to service

• Part 21 project managementContact person: [email protected]

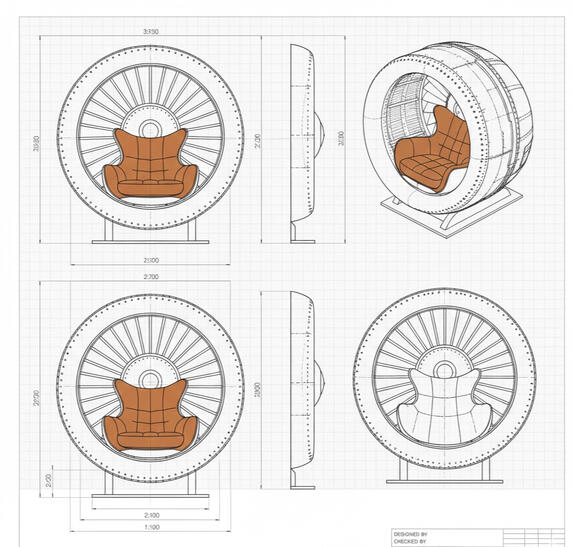

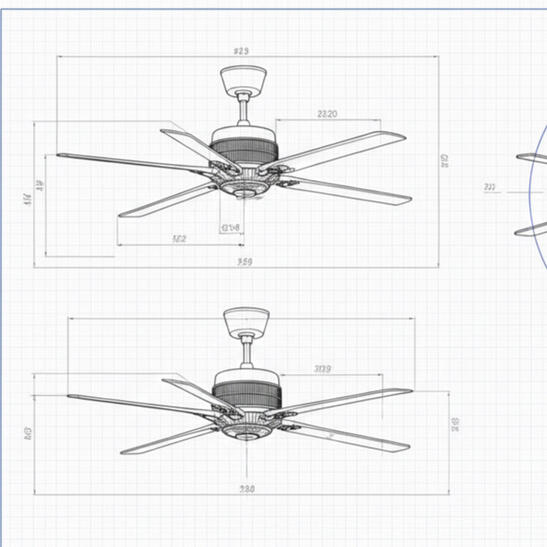

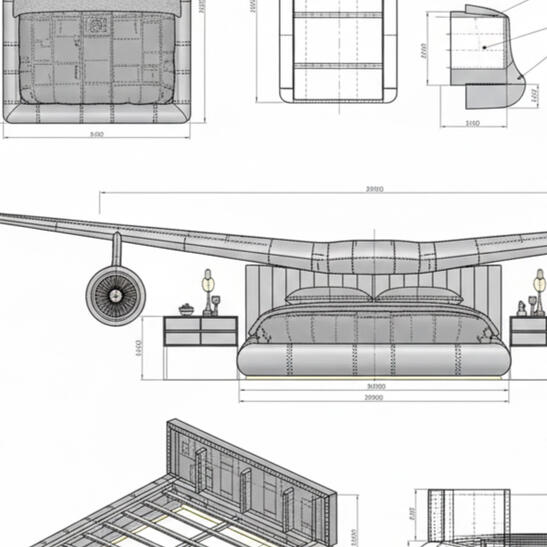

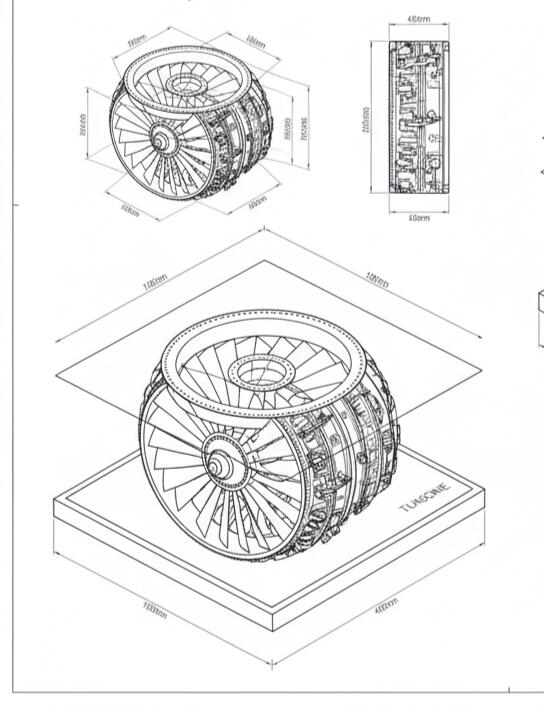

Aircraft-inspired seats and custom furniture components

It may sound unusual, but transforming aircraft parts into stylish, functional furniture isn’t just a wild idea - it’s absolutely possible. Here you’ll find concept pieces that show how aviation aesthetics can become stunning interior elements.Prices start at 10,000 EUR. Use discount code 0021 for an exclusive offer!

Bank details:

Benificiary Name: UAB "AEROMETALO PRODUKTAI"

Address: Meistrų g. 8-101, LT-02189 Vilnius, Lithuania

Phone: +370 695 64785

Email: [email protected]

Bank information: AB „Artea“ Tilžės g. 149, 76348 Šiauliai

IBAN: LT487180300029467133

BIC: CBSBLT26XXX

Projects

GET IN TOUCH